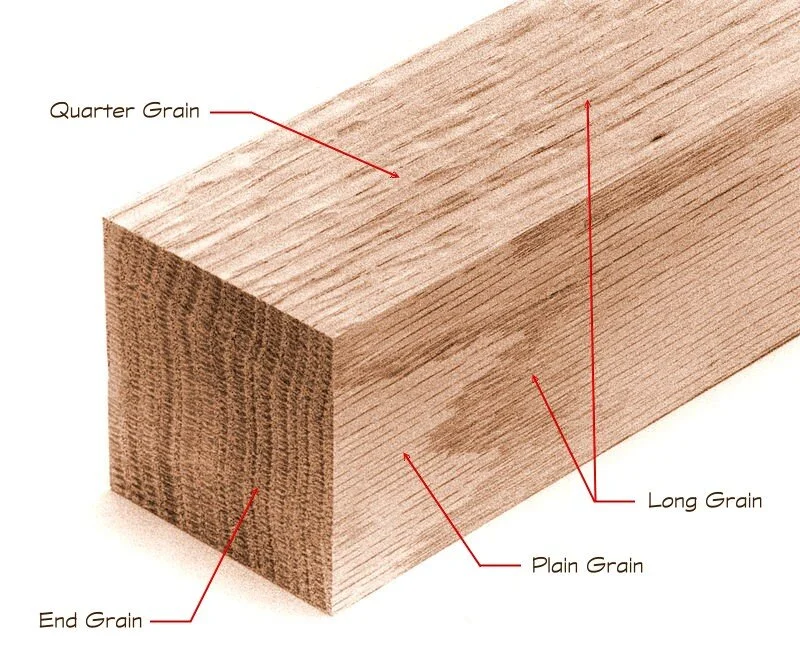

Edge-Grain Vs. End-Grain

Some of you have asked why some of the boards are tagged “End-Grain” and what that means. The simplest way to describe it is with pictures. If youve ever see a tree stump you’ve seen tree rings. When a tree is cut traditionally its sliced long ways into slabs or squares then shipped off to its destination. In the picture above you can see how the long sides are relatively smooth and similar, thats the “edge” of the wood, hence “edge-grain”, or “face-grain” depending. The shorter side where it was cut is the “end” of the board hence “end-grain”

“Edge-grain”

Why does it matter?

By nature the end grain pieces are going to be smaller so to make one takes more time and more effort, so why go through the trouble? Simply put.. your knives. Think of the wood grain like this bamboo figure (Forged in Fire is a great show Im addicted and you should be watching it. This is not an ad though)

Still from The History Channel/Netflix’s “Forged in Fire”

If you cut into the edge you do the most damage, the marks are easy to see and provide the most force against the knife. If you were to cut from the top it would slide in deeper and easier because you’d only be hitting the top ends of the stalks. When you slid the knife out the stalke would slap back into place like it was never there. Its the same with wood. The grains would be facing upward does less damage to your knives and doesnt show scratches as easily.

“End-grain”

In Short

Edge-Grain: Pretty face, over time harder on knives

End-Grain: Looks like the curves of a tree ring, Easier on Knives, Harder to make